Look out for part two of our series to reveal what measures have already been taken and the potential extent of progress that can be achieved.

AI and Automation: The Future of Semiconductor Manufacturing (Part One)

28. June 2023

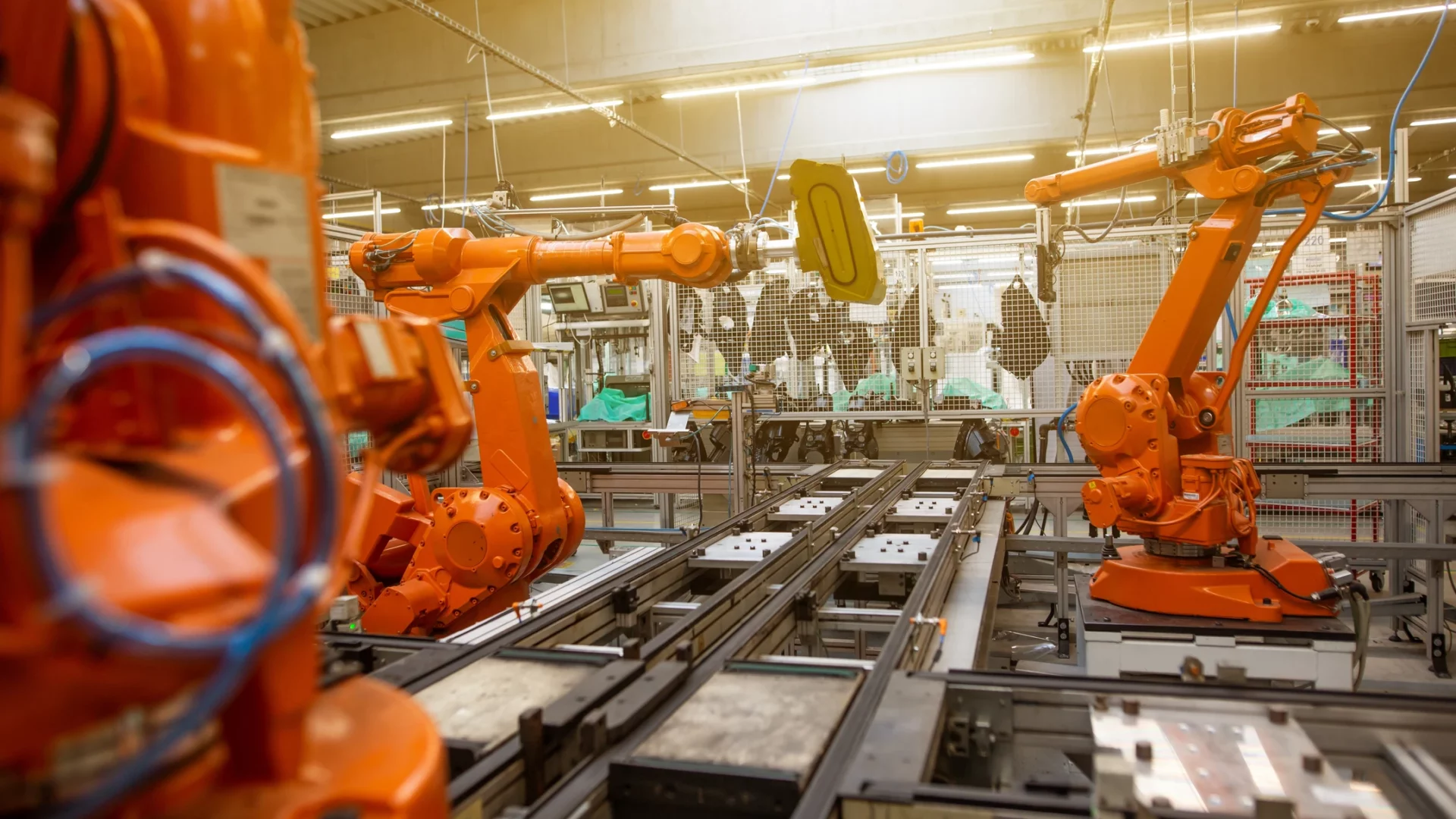

The semiconductor industry is on the verge of a revolution. The integration of artificial intelligence (AI) and advanced automation technologies opens up whole new possibilities for more flexible production, more diverse products, and optimized processes. However, leveraging these technologies is also complex, and not all the groundwork has been laid.

The semiconductor industry is known for its use of complex automation technologies, especially for repetitive tasks and standardized procedures. However, the expanding market demands more flexible production, more diverse products, and optimal processes with increasing complexity. Semiconductor manufacturers are striving for more autonomous operations, including better human-machine interactions. This is exactly where artificial intelligence (AI) can provide support.

New ground for industrial AI

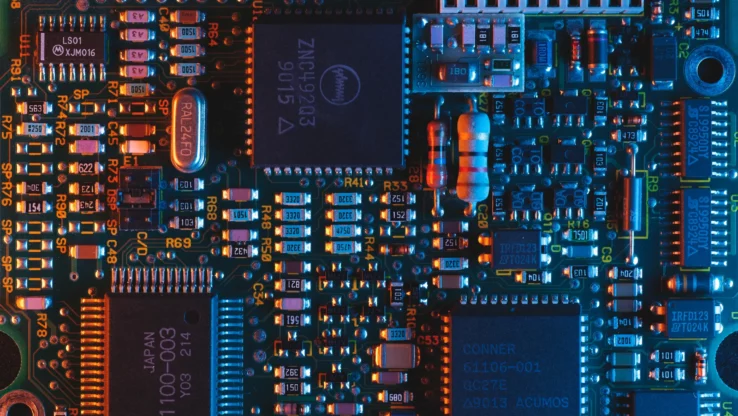

Some AI technologies are already in use in many areas of the semiconductor industry. These are being used to support product development, digital product definition (DPD), and knowledge management for risk assessment and root cause analysis. They are also used in front- and back-end applications for image recognition, inspection, and defect categorization. In addition, simulations and virtual testing accelerate prototyping. As a result, development times are significantly reduced.

However, research in the field of machine learning (ML) as well as specific information processing methods such as deep learning (DL) are gaining momentum. These techniques aid in addressing the unique challenges of semiconductor manufacturing. Because engineering and technology are always evolving, the number of process parameters that must be managed, such as temperature during the etching process, is increasing.

AI serves a dual purpose in the semiconductor industry: it is a key component in digitizing manufacturing processes and provides semiconductor producers with tools to improve operations and manage process parameters as technology moves toward the nanoscale level. Despite the obvious benefits, a survey of semiconductor manufacturers found that approximately 30 percent of companies are using AI/ML in production.

Old laws are out, new technologies in

The demands on semiconductor factories (fabs) are many and increasing. They need a diverse product range, shorter production cycles, and quick product changes while maintaining high quality and low costs. In production, most manufacturers rely heavily on advanced process control (APC) techniques. Their entire infrastructure is designed to provide customized APC systems off the shelf at any time. This will remain a cornerstone in the future, but it will be progressively complemented by technologies such as AI and the industrial internet of things to be more flexible.

Experts also agree that Moore’s Law’s grand calculus has reached its limits. It has long been regarded as the driving force for innovation in the field of integrated circuits (IC), claiming that the complexity of ICs doubles on a regular basis with minimal component costs. Still, exponential growth cannot be sustained because the components cannot physically become any smaller without encountering quantum mechanical effects, such as the tunnel effect. This enables electrons to pass over a barrier that they would otherwise be unable to overcome. This would cause unwanted leakage currents in the transistors, rendering the ICs unreliable and underperforming. Further breakthroughs require new semiconductor technologies, which would require complex manufacturing facilities equipped with advanced metrology systems. AI could work out new ways and methods in simulations using sensors and data collected, avoiding lengthy experiments and setbacks.

Data is the most important resource

That said, there are difficulties in implementing AI in the semiconductor industry. A major hurdle is a lack of high-quality data required to train AI algorithms. This can include process, sensor, and measurement data, as well as historical and external data. Every aspect of semiconductor production essentially depends on accurate and reliable data from critical dimensions, lithographic pattern design, and material composition.

There is also a lack of trained personnel in many places to train and implement the systems. The entire process requires a change in companies’ mindset, as well as a willingness to adopt and integrate new techniques and technologies. Competitive pressure is increasing on semiconductor manufacturers to reduce production timelines and costs, improve quality, shorten innovation cycles, and accelerate the introduction of new technologies.