Our Services

Test procedure at a glance

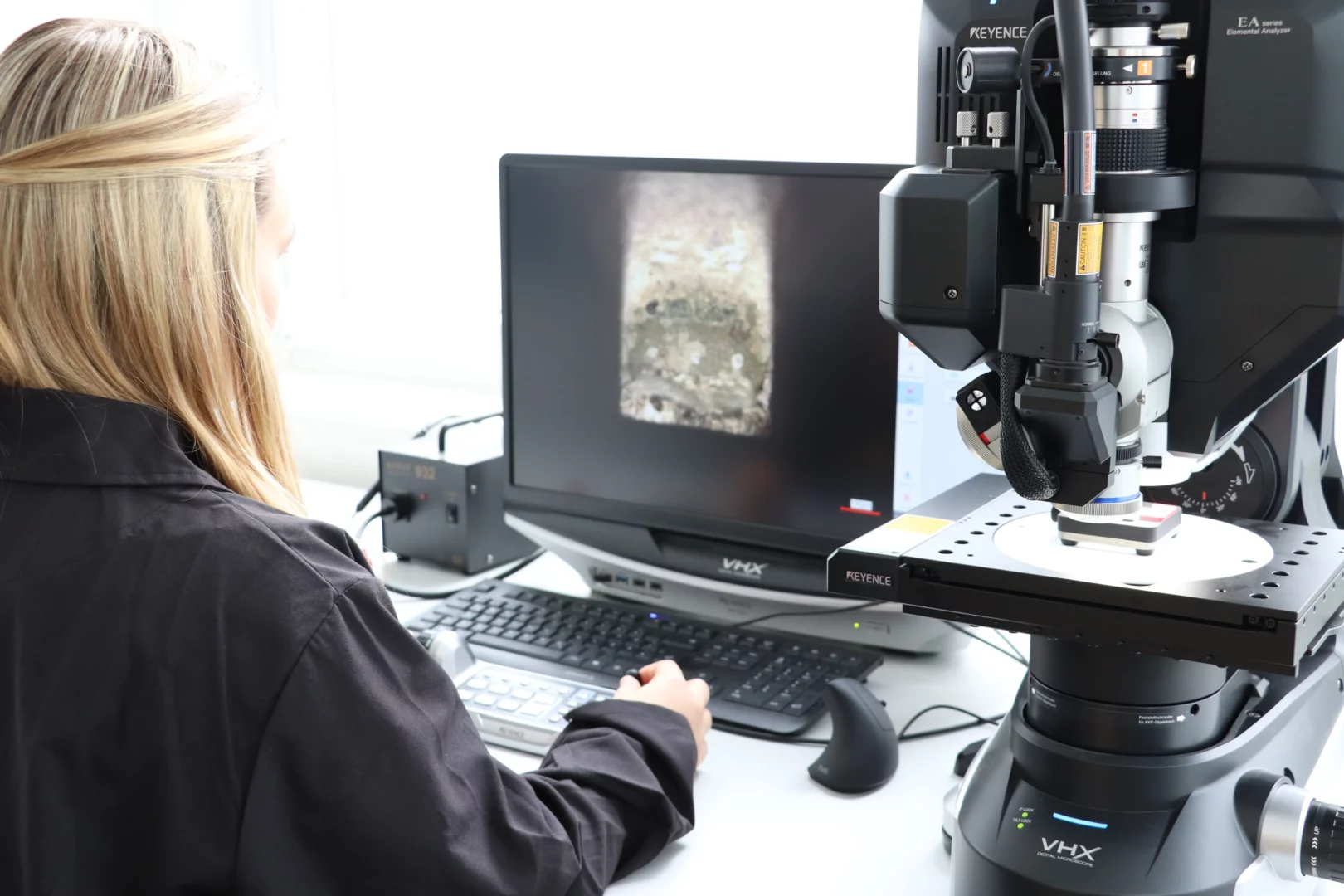

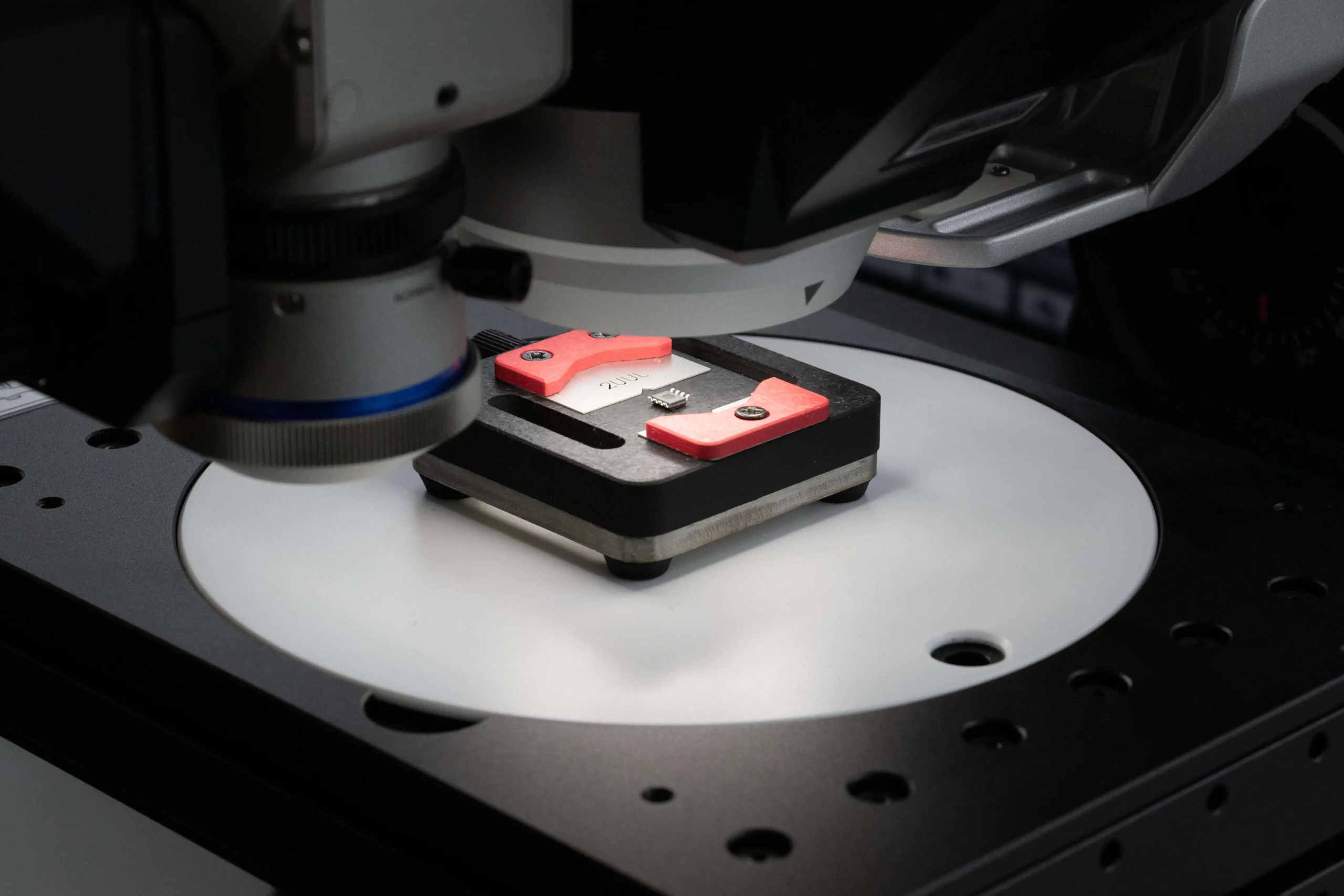

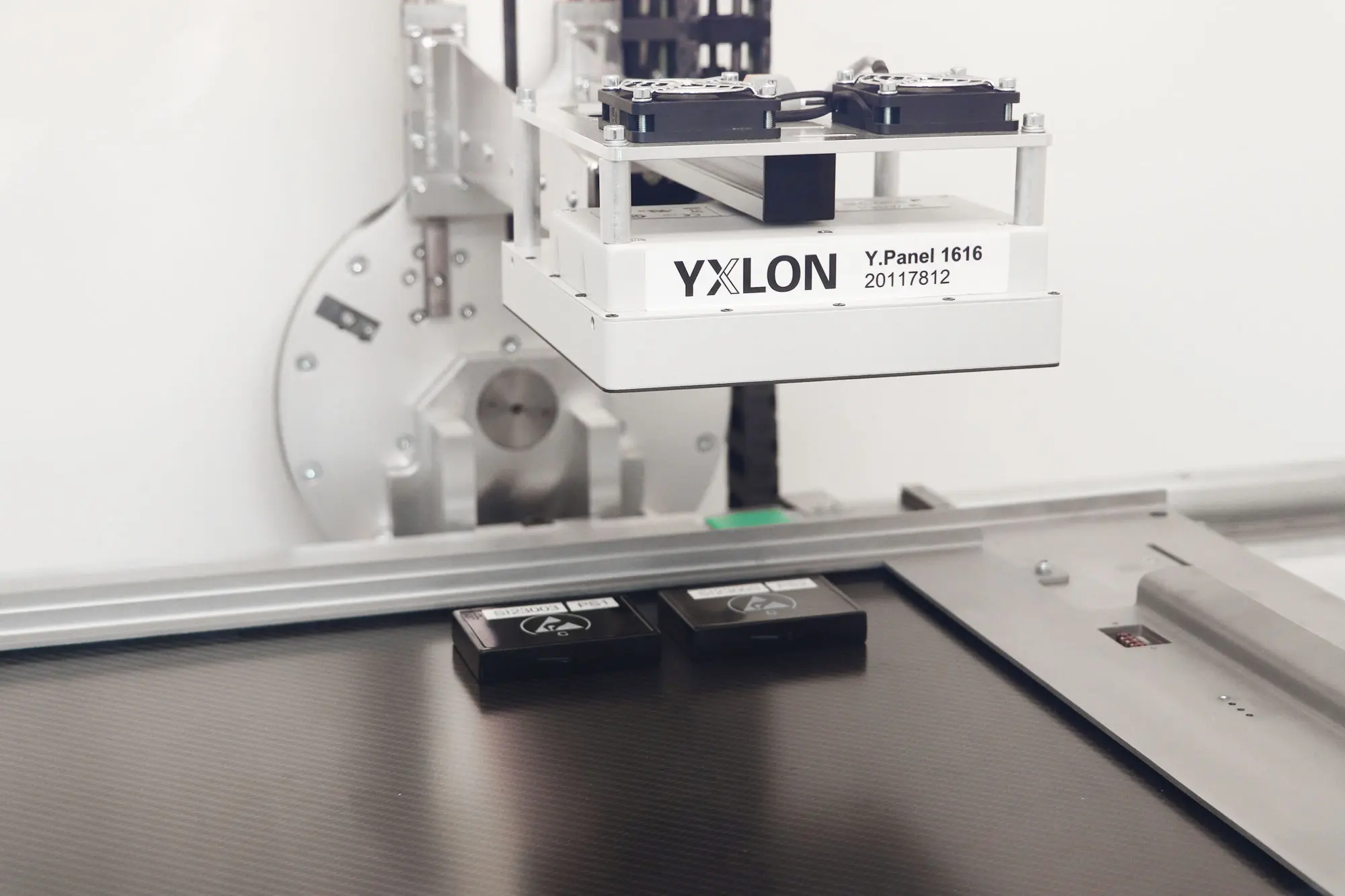

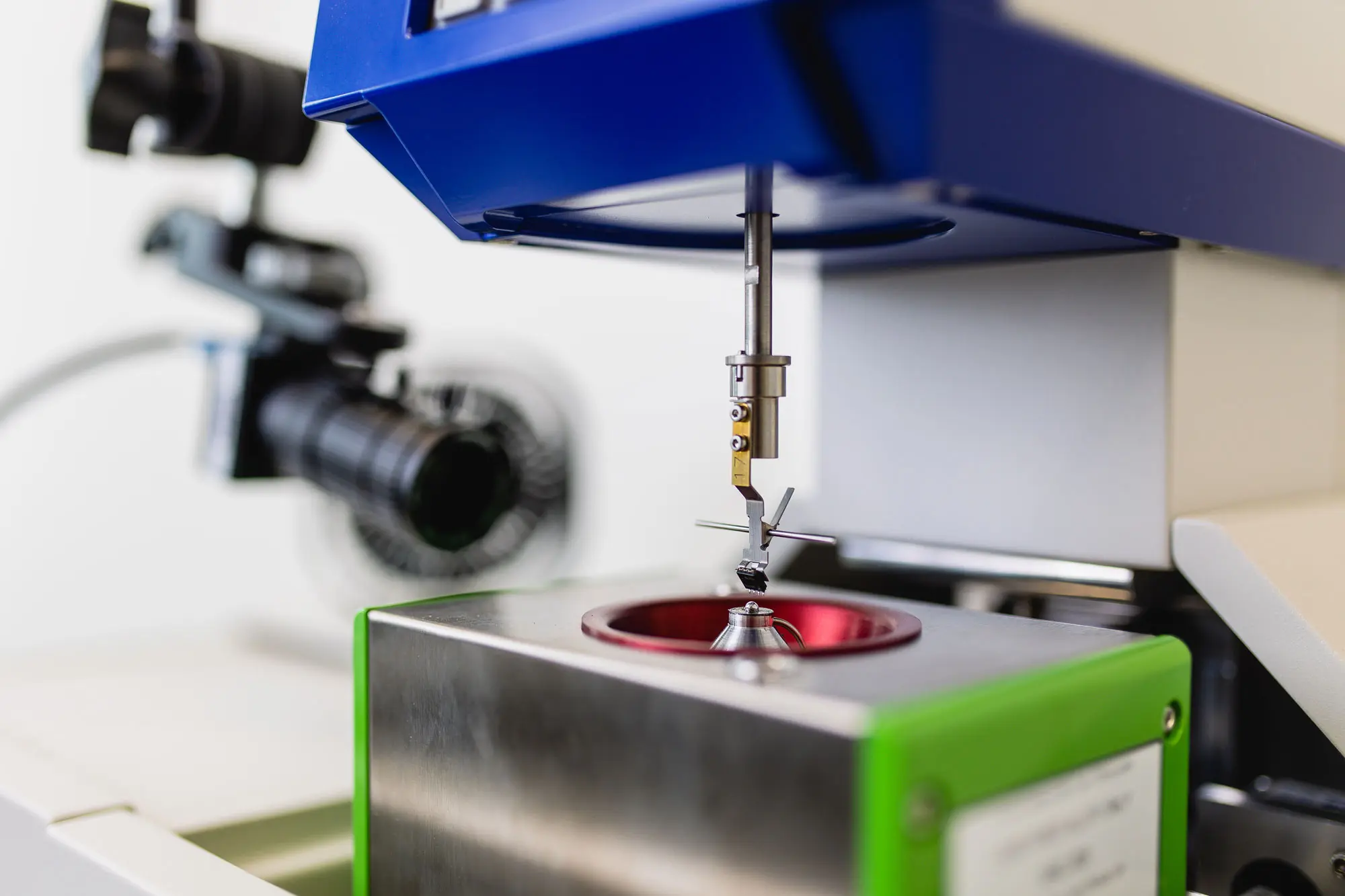

Our experienced team tests your electronic components. According to standardized procedures. With the latest technologies.

Advantages at a glance

Your contact

Dr.-Ing. Paul Braun

Global Director Quality, Control & Research

As an expert in the field of semiconductor technology and author of publications on, for example, component falsification and the popcorn effect, Dr. Paul Braun is head of the SI TechLAB. He gained his in-depth knowledge at the TU Darmstadt, where he completed his doctorate in materials science.

As the best materials tester of his graduating class at Rittal RGS, Dr. Braun brings both in-depth theoretical knowledge and broad practical experience to establish the SI TechLAB as a center of technological excellence.